PRODUCT CENTER

CONTACT US

© 2019 Jinding waterproof technology All rights reserved. 鲁ICP备13022271号-2 Powered by www.300.cn

NEWS

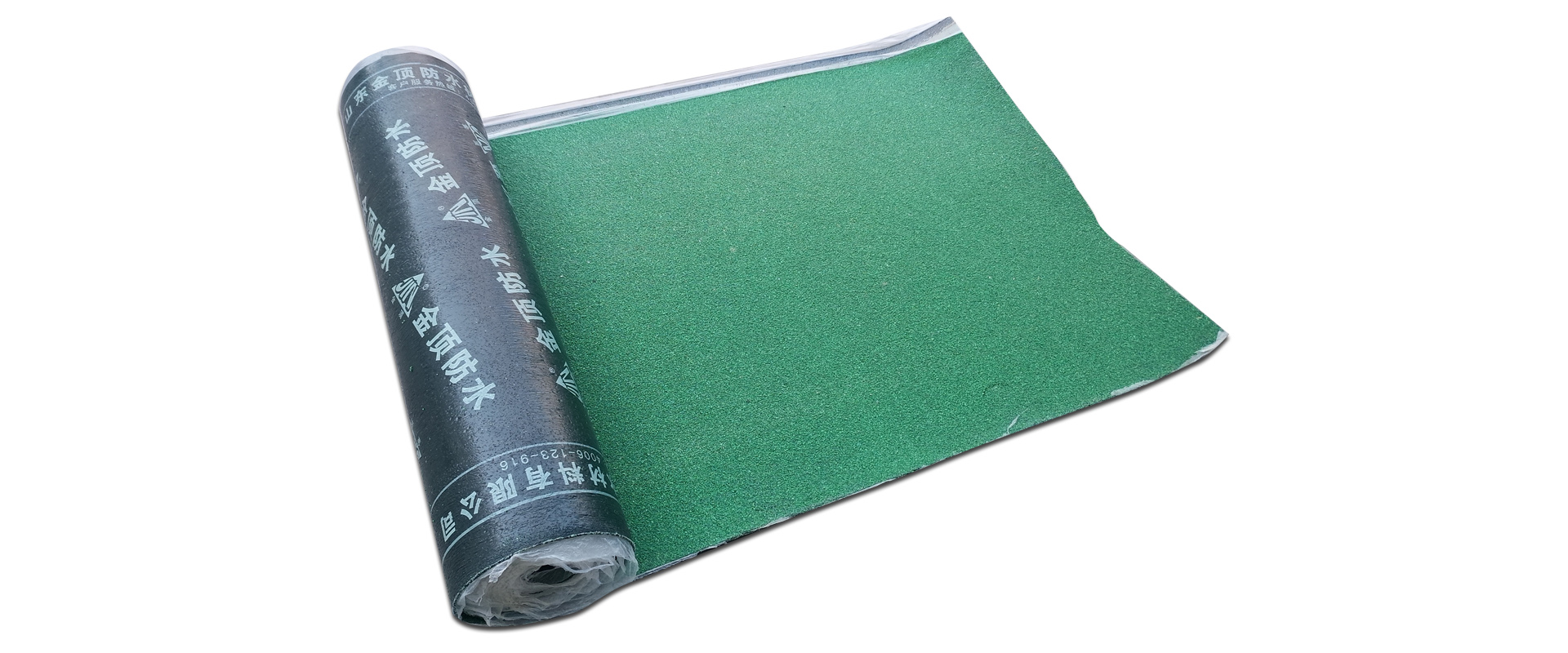

WATERPROOFING MEMBRANE MANUFACTURER

Basic surface treatment of sbs waterproofing membrane

The sbs waterproofing membrane manufacturer tells you that the building envelope should prevent the penetration of rainwater, snow and groundwater; it should prevent the corrosion of moisture, steam and other harmful gases and liquids in the air; the separation structure should prevent water supply and drainage leakage. These impermeable, anti-leakage and corrosion-resistant materials are collectively referred to as sbs waterproofing membrane. Next, I will introduce the basic surface treatment of sbs waterproofing membrane.

1. The substrate must be firm, flat, clean, free of dust, greasy, wax, release agent and other debris.

2. If there are pores, cracks and uneven defects on the bottom surface, repair and polish with cement mortar in advance.

3. The sbs waterproofing membrane manufacturer tells you that it is recommended to paste plastic strips on the expansion joints and add a layer of non-woven fabrics on the expansion joints.

4. The inner and outer corners should be drawn in circular arcs.

5. Make sure the bottom surface is moist enough, but there is no clean water;

6. The sbs waterproofing membrane manufacturer tells you that the newly poured concrete surface should be completely dry before construction.

The above is the knowledge about the basic surface treatment of sbs waterproofing membrane, I hope it can help everyone.