PRODUCT CENTER

CONTACT US

© 2019 Jinding waterproof technology All rights reserved. 鲁ICP备13022271号-2 Powered by www.300.cn

NEWS

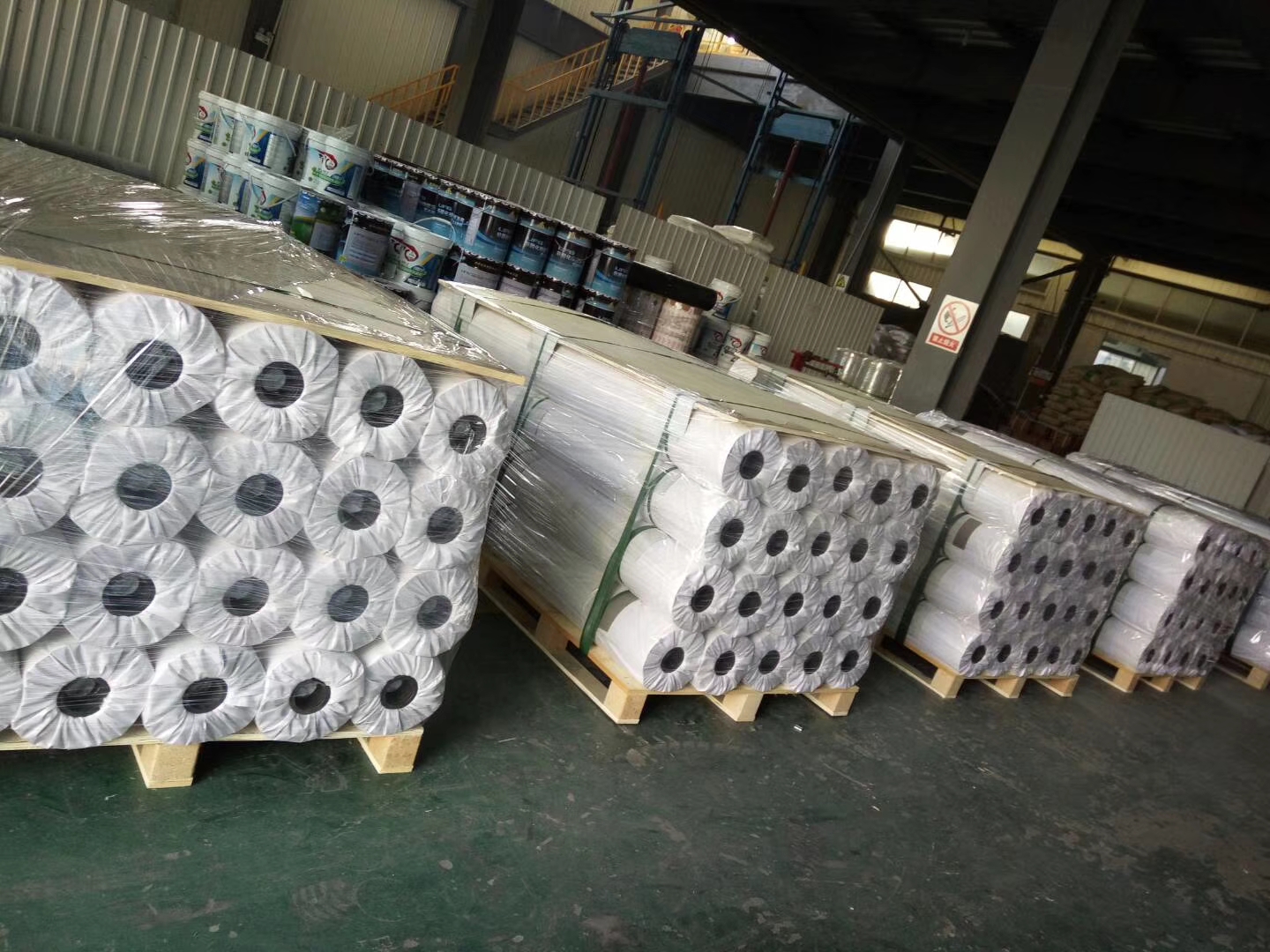

WATERPROOFING MEMBRANE MANUFACTURER

Do you know the correct laying method of pre-applied HDPE membrane

The pre-applied HDPE membrane is a plastic coil composed of HDPE, which is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE has excellent resistance to most household and industrial chemicals. The following will take you to understand the correct laying method of pre-applied HDPE membrane.

1. Before laying the pre-applied HDPE membrane, the corresponding qualification acceptance certificate of the civil engineering shall be obtained.

2. Before the HDPE film is cut, its relevant dimensions should be accurately measured, and then cut according to the actual size. Generally, it is not suitable to cut according to the size shown in the figure. It should be numbered one by one and recorded in detail on the special form.

3. When laying the pre-applied HDPE membrane, the minimum number of welds should be sought, and the raw materials should be saved as much as possible on the premise of ensuring the quality. At the same time, it is easy to guarantee the quality.

4. The lap width of the seam between the film and the film is generally not less than 10cm. Usually, the direction of the welding seam is parallel to the maximum slope, that is, it is arranged in the direction of the slope.

5. Usually in corners and deformed areas, the length of the seam should be shortened as much as possible. Except for special requirements, on slopes with a slope greater than 1:6, within 1.5 meters from the top slope or the stress concentration area, try not to set welds.

6. During the laying of the pre-applied HDPE membrane, artificial wrinkles should be avoided. When the temperature is low, it should be tightened as much as possible and flattened.

7. After the pre-applied HDPE membrane is laid, walking on the membrane surface, moving tools, etc. should be minimized. Any objects that can cause harm to the impermeable membrane should not be placed on the membrane or carried on the membrane for walking. To avoid accidental damage to the membrane.